Heat Treatment

The specialized module allows for the prediction of the structure and mechanical properties of structural and low-alloy steels after undergoing heat treatment: quenching, normalizing, or annealing.

- Temperature and phase fields

- Slab solidification

- Macro and microporosity

- Residual stresses

- Cracks (hot and cold)

- Elastic deformations

- Plastic deformations

- Metal structure

Cost and Time Reduction

Save significant costs in materials and labor, in addition to reducing product development time.

Improve Quality and Precision

Prevent and correct casting defects, such as porosity, air inclusions, or solidification issues.

Process and Design Optimization

Experiment with different variables of the casting process to find the most efficient configuration.

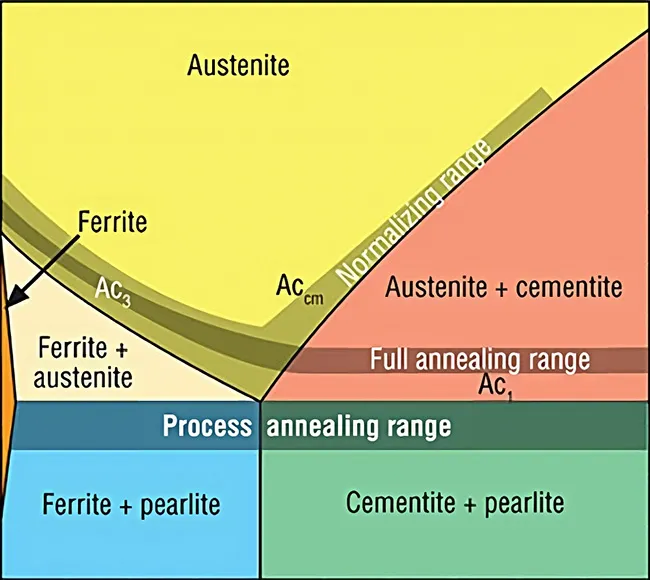

Heat Treatment Model

The model enables the prediction of metal characteristics following heat treatment.

Input Parameters:

Fourier Solver:

Heat Treatment Module:

Simulation of:

- Quenching

- Normalizing

- Annealing

- Tempering

Results:

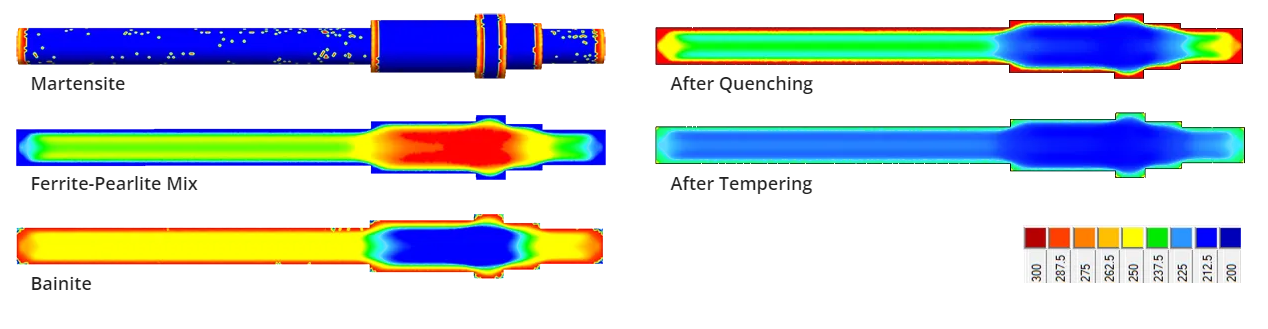

- Structure (martensite, bainite, ferrite-pearlite mix)

- Vickers Hardness

- Yield Strength

- Tensile Strength

- Relative Elongation

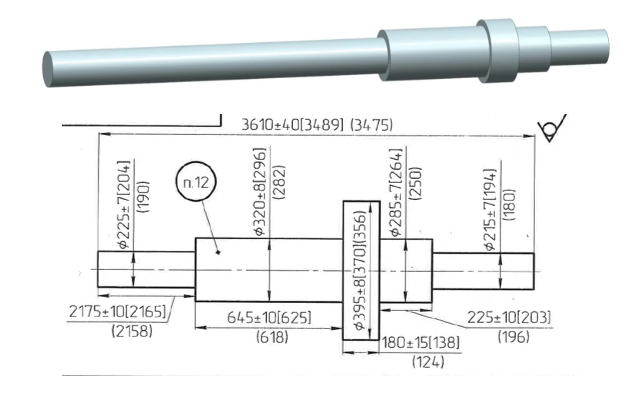

Heat Treatment of 40Х Steel Shaft

A study conducted to understand the causes of the fracture of a shaft after heat treatment performed by the producer.

- Oil Quenching

- Initial Temperature of the Shaft: 1000 °C

- Heat Transfer to Oil: 1500 W/(m²K)

- Retention Time: until the surface temperature reaches 200 °C

- Air Cooling: Down to 20 °C

- Heat Transfer to Air: 10 W/(m²K)

Structure

Result of the calculation of the metal structure after quenching

Vickers Hardness

Result of the calculation of Vickers hardness after quenching and tempering

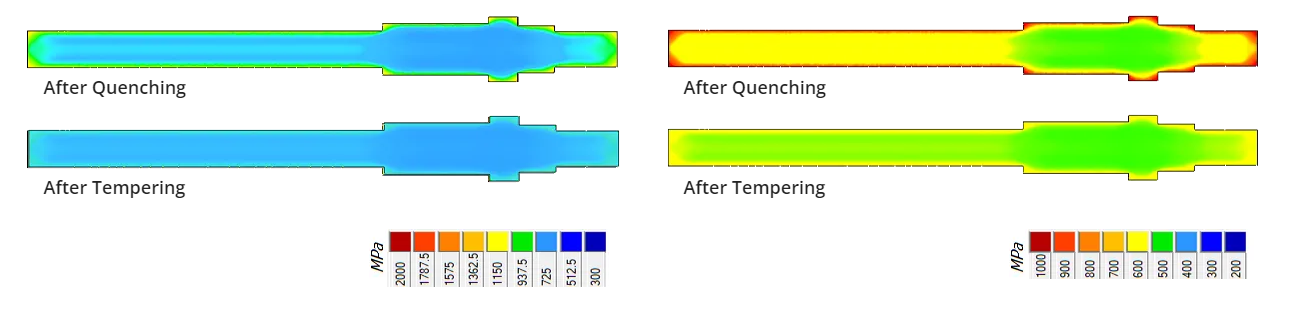

Tensile Strength

Result of the calculation of tensile strength

Yield Strength

Result of the calculation of yield strength after quenching and tempering