Sand Casting

The use of simulations allows verifying and studying the effectiveness of the technology and observing the internal processes occurring in the casting.

- Shrinkage cavities

- Residual stresses

- Macro and microporosity

- Cracks (hot and cold)

- Deformations and warping

- Metal structure

Modeling enables the avoidance of the defect correction stage, reduces the costs of readjusting equipment in terms of both time and materials, and minimizes the number of trial castings when launching new products into production.

Cost and Time Reduction

Save significant costs in materials and labor, in addition to reducing product development time.

Improve Quality and Precision

Prevent and correct casting defects, such as porosity, air inclusions, or solidification issues.

Process and Design Optimization

Experiment with different variables of the casting process to find the most efficient configuration.

Process Optimization

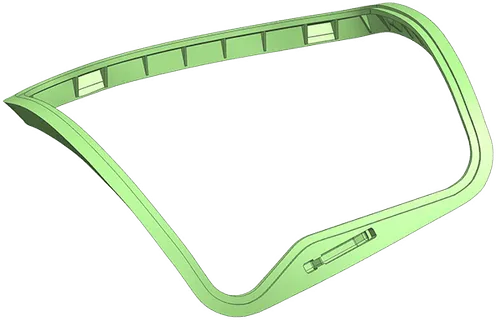

The process of optimizing the casting technology for a helicopter cabin frame is demonstrated. The primary goal is to reduce the cost of technology by minimizing the use of expensive thermal insulating materials and simplifying the complexity of mold assembly.

- Magnesium Alloy - ML5pch

- Mold - Cold-Setting Mixtures to Alpha-Set

- Isothermal Insulators - FOSECO

- Pouring Temperature - 760°C

- Casting Block Mass - 55.3 kg

- Casting Mass - 9.8 kg

Helicopter Window Frame produced by a company within the Russian Helicopters holding

Defective Technology

The previous technology allows for obtaining a casting suitable for use; however, the cost, labor intensity, and quantity of defective products are high.

Analysis indicated that the technology is not stable enough.

The casting solidifies almost simultaneously with the feeder system. This means that with minimal changes in the technology parameters (such as the temperature of the molten metal), shrinkage porosity can form in the body of the casting.

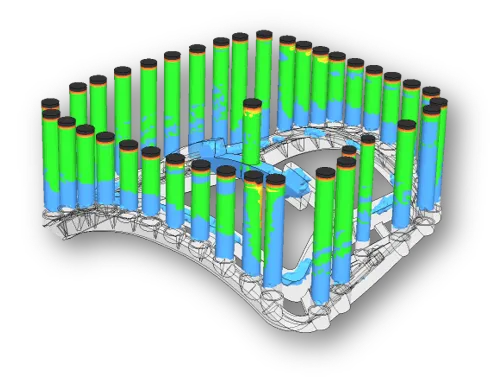

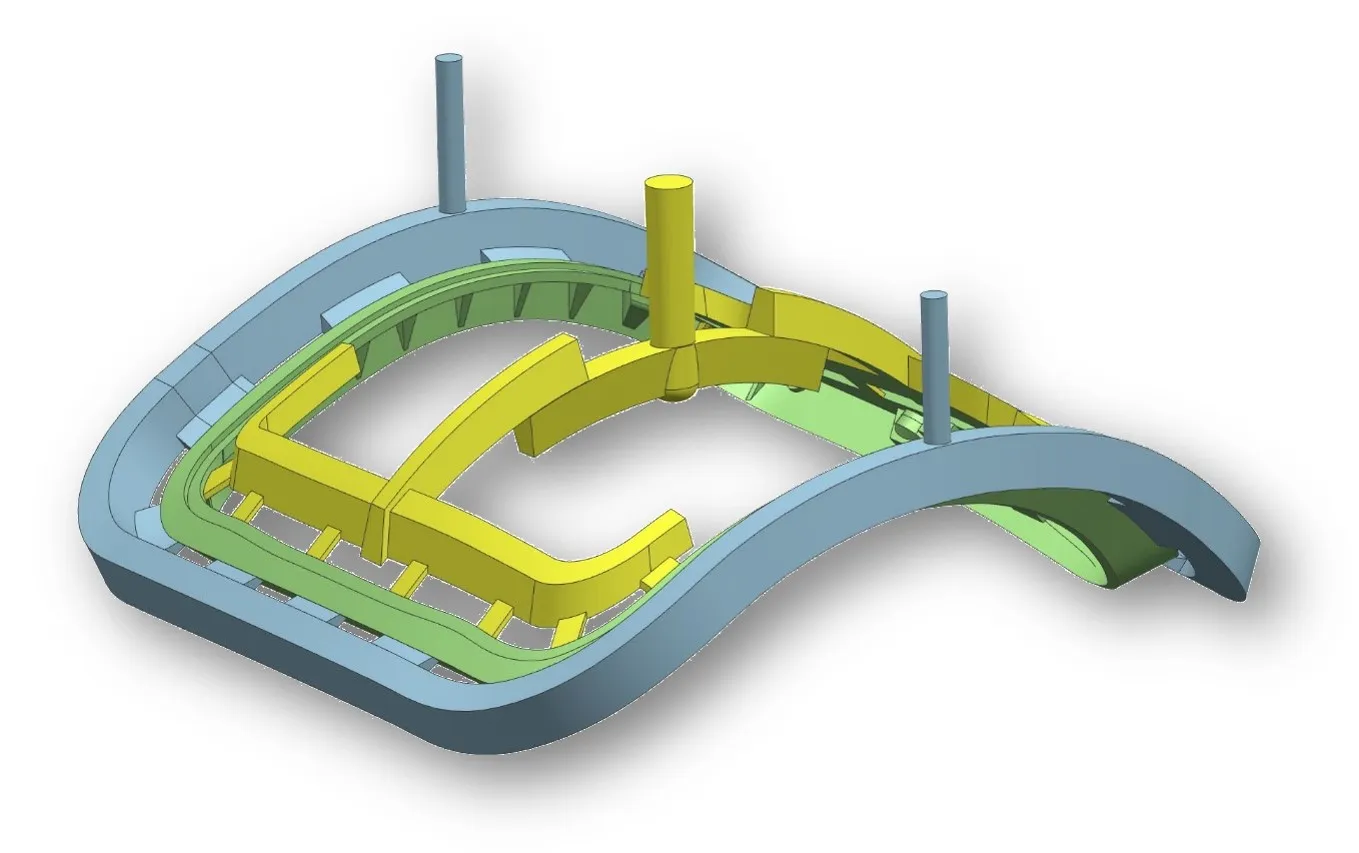

Modification 1

To achieve a defect-free casting and decrease costs, a change was made in the design of the gating system. The vertical feeders were replaced by a single lateral feeder without thermal insulation. The concept of the central feeder remained unchanged.

Porosity levels are within the established limits for manufacturing.

High levels of residual stresses and plastic deformations are observed.

Result

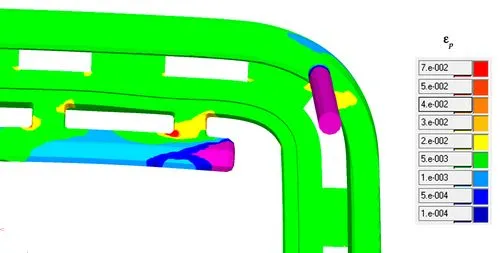

Intensity of Plastic Deformations

The calculations made allowed the identification of the cause of cracks at the intersection of the casting with the gating and feeder system.

An improved version has been developed with a lower level of residual stresses, which allows for defect-free castings.

The developed design has been implemented and is currently used in helicopter manufacturing.

Porosity Analysis

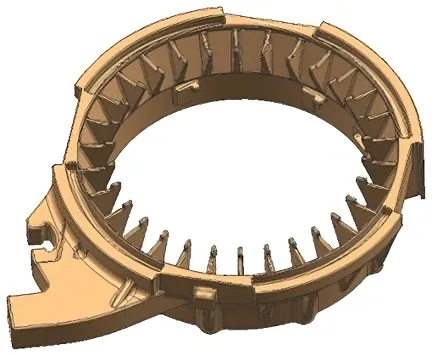

Manufacture of an experimental batch of "Stator Ring" castings at the SIEMENS company.

The first casting made according to the company's technology contained defects:

- Incomplete filling of the teeth on the inner surface.

- Porosity in the area of the feeders.

Defective Technology

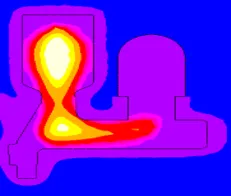

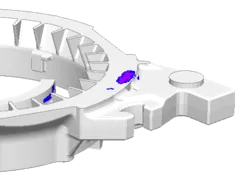

Simulation in PoligonSoft helped to understand the causes of the defects...

Cross-section of the temperature field in the porosity area shows the formation of un-fed thermal nodes.

The porosity exit zones to the surface detected in the simulation coincide with the experimental result.

Result

... modifying the technology to achieve a casting suitable for use.

Final Result - a defect-free piece

Prevention of Hot Cracks

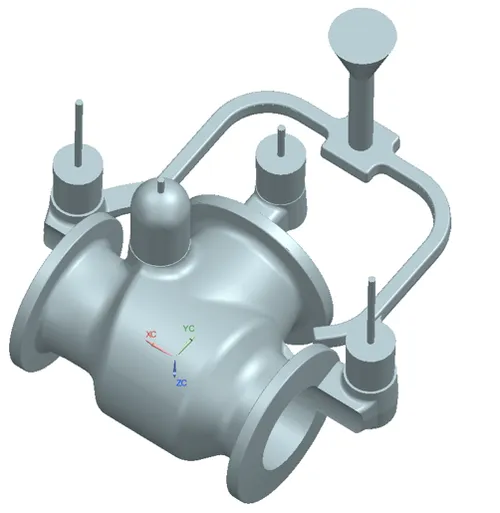

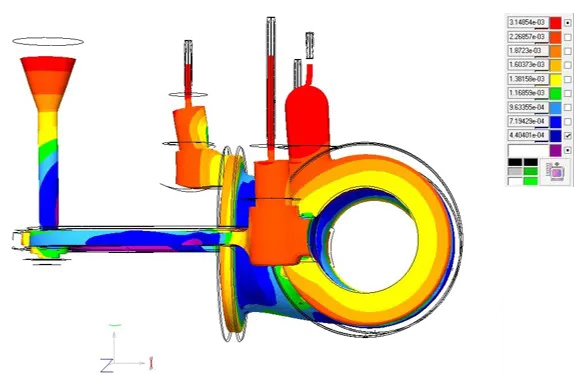

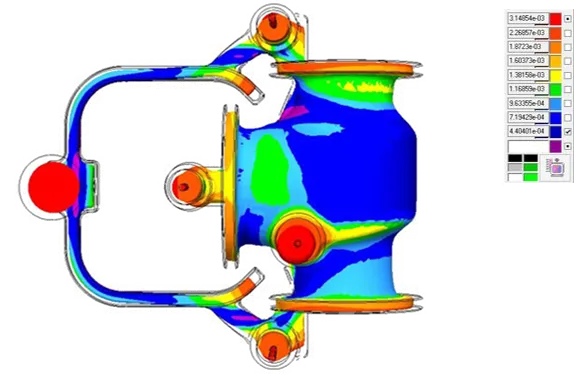

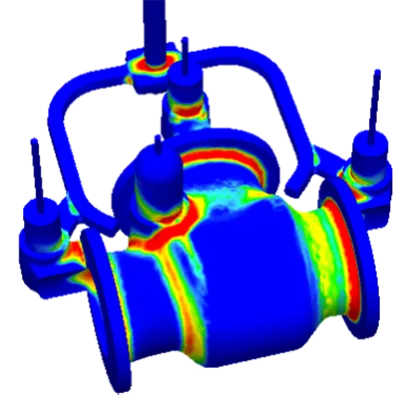

Simulation of the casting process of an industrial valve body is shown. The main objective is to verify the reliability of our hot crack prediction system.

- Incomplete filling of the teeth on the inner surface.

- Porosity in the area of the feeders.

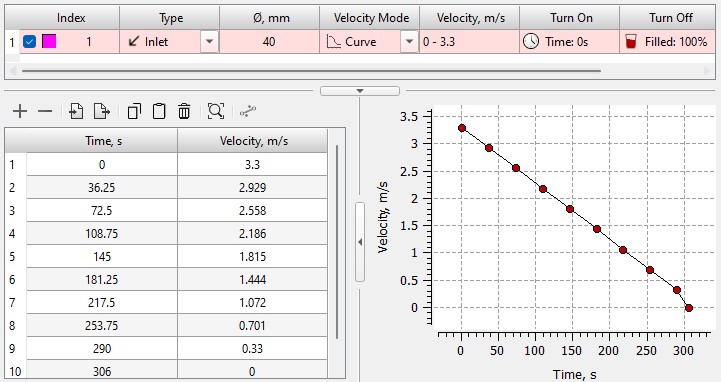

Holding ladle parameters

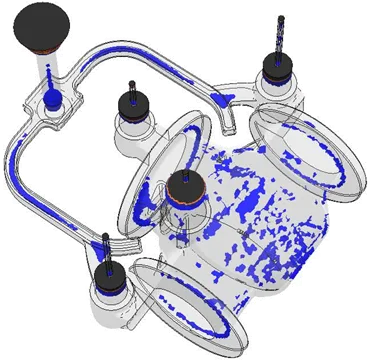

Mold Filling

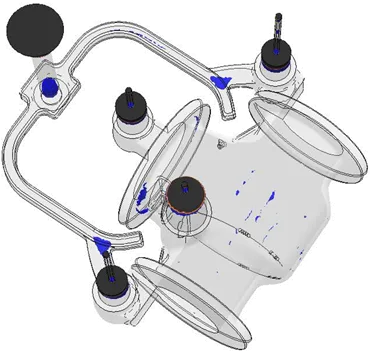

Solidification

Porosity

Porosity of 0.7% and above

Porosity of 0.8% and above

Porosity of 1% and above

Deformation

Result

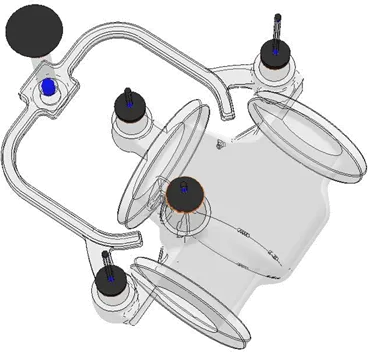

Hot Crack Indicator

Verification of results

The mathematical model of stress and deformation state of the casting developed by "PoligonSoft" is capable of predicting with high probability the formation of hot and cold cracks.

The simulation of most modern casting technologies requires considering the contact interaction between the casting and the mold, as this interaction is often the cause of crack formation.

The ability to predict crack formation at the design stage significantly reduces the time and expenses required to adjust and optimize the technological process.