The quality and reliability of calculations are directly related to the ability to simulate the end-to-end process.

At PoligonSoft, all stages of the casting production process can be sequentially simulated: mold heating, mold filling with molten mass, solidification on the bench or in the thermostat, extraction of the cast part from the mold, cutting of the feeding system and risers, etc.

Step-by-Step Implementation

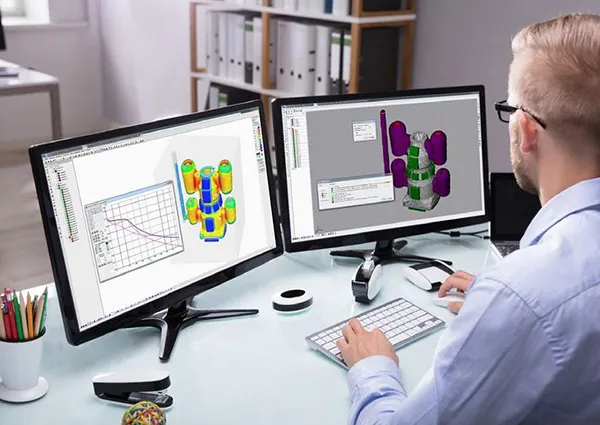

Check in real simulations of your foundry how PoligonSoft helps to solve your problems.

Step

01

Furnace Startup

Core Setting in the Mold

Pre-heating of the Mold

Step

02

Furnace Startup

Core Setting in the Mold

Step

03

Thermal stabilization

Mold extraction

Removal of the gating system

The PoligonSoft software includes a variety of models and solvers, designed to address different issues that arise during casting stages.

MESH

Finite Element Mesh Generator.

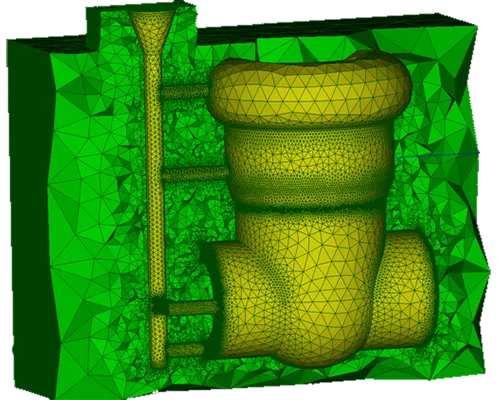

PoligonSoft uses the modern and accurate finite element method to ensure that the surface and volume of the casting model match the original as closely as possible.

The user decides where maximum detail is required and where a coarser mesh can be used to maximize computational resources.

- Import in IGES and STEP formats

- Automatic creation of conjugated surfaces

- Tools for geometry correction

- Adjustable element size

- Algorithms for mesh quality correction

- Construction of tetrahedral and other types of meshes

- High level of automation

- No "manual" mesh editing required

Mesh Quality Control

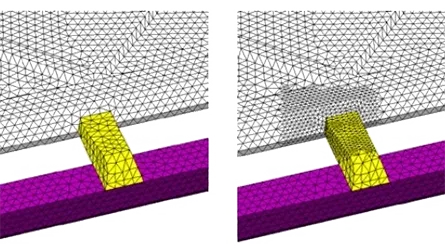

The integrated editing and quality control functions of the finite element model allow for rapid manipulation of the mesh without needing to rebuild it in the mesh generator.

Mesh quality inspection tools based on predefined parameters identify elements with critical angles or irregular shapes and correct or eliminate them.

Special tools analyze the geometry for thin walls and locally refine the mesh to improve calculation accuracy.

MASTER

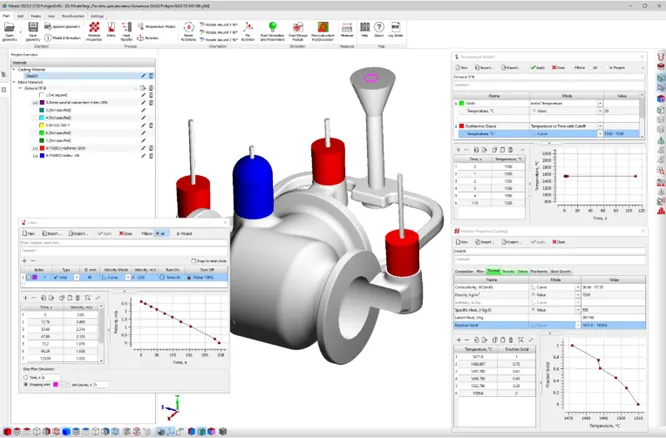

Preparation of the element model for subsequent calculations.

In the design process, it is often necessary to calculate many variants of the gating system and risers or technological regimes. In this process, usually, only the geometry of the casting block or the pouring temperature changes, while all materials and heat transfer conditions remain unchanged.

To avoid routine operations when starting the calculation, PoligonSoft uses templates of technological processes, which provide the user with already tested and characteristic data sets for each technology.

- Import of finite element meshes from virtually all known CAE systems (ANSYS, NASTRAN, NX, SolidWorks, Visual Environment, FEMAP, HyperMesh, etc.)

- Automatic construction of shells for investment casting

- Inheritance of all calculation configurations to new models

- Materials databases

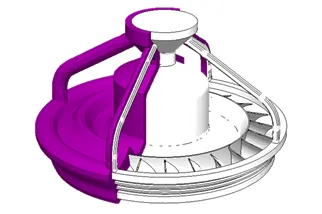

Ceramic Mold Generator

In investment casting, the ceramic mold has a geometry defined by its thickness and the shape of the wax master model surface.

The shell generator allows creating a mesh model of the ceramic mold with a specified thickness without any prior construction in the CAD system. This way, uncomplicated elements like covers, coatings, insulating and exothermic mixtures, etc., can be modeled.

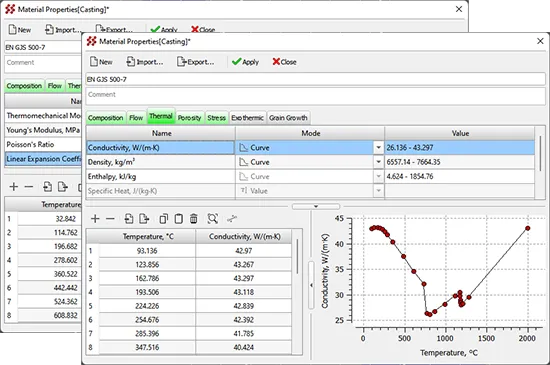

Materials Database

PoligonSoft comes with a database of materials and alloys, including the properties of many steels, cast irons, aluminum, nickel, titanium, copper, zinc, and precious alloys.

It contains materials for molds: sands, ceramics, insulating and exothermic sleeves, and many other materials used in casting. The database can be edited and updated by the user.

FOURIER

Solidification and Porosity Solver.

The thermal solver "Fourier" calculates temperature and phase fields, considering heat transfer (by conduction, convection, radiation) and the heat release during solidification.

Fourier allows for complex multi-stage calculations during which cooling conditions and model geometry can be changed.

The module enables the calculation of:

- How temperature fields change in the casting and the mold

- Identification of thermal nodes in the casting

- Detection of overheating areas in the mold

- Calculation of shrinkage sinking

- Shrinkage cavities, macro and microporosity

- Hydrostatic pressure

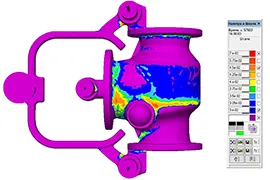

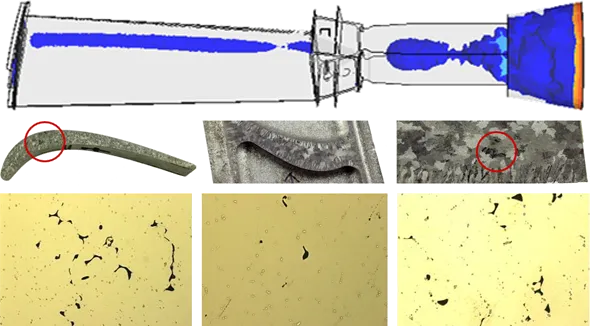

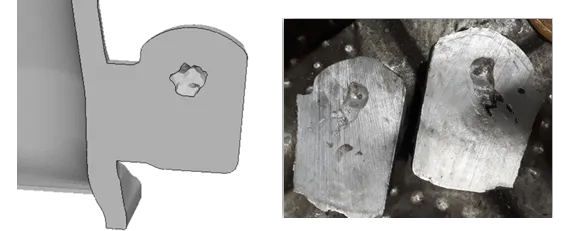

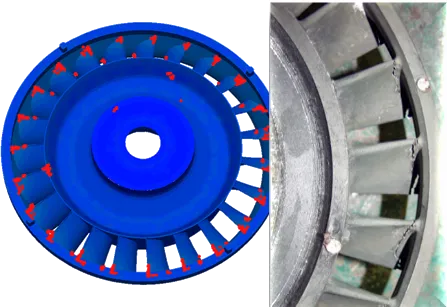

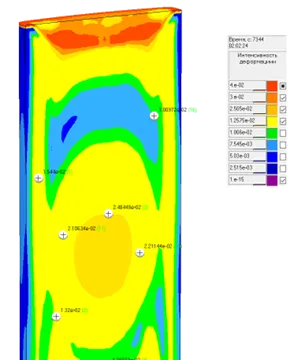

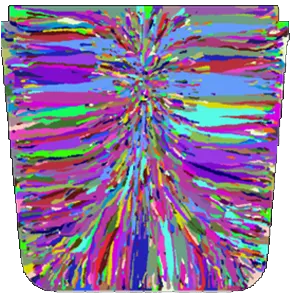

Shrinkage Macro and Microporosity

One of the apparent advantages of PoligonSoft is the model of macro and microporosity of shrinkage, which allows predicting the formation of defects in critical use castings (turbine working and nozzle blades, monoblock wheels, pump impellers, etc.)

Special algorithms that consider the capillary effect and the pressure drop during the solidification of closed thermal nodes allow for more accurate calculation of the defect pattern

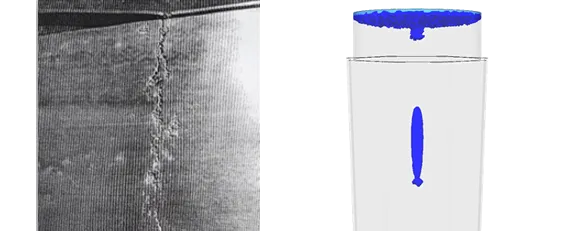

Shrinkage Cavities in Steel Casting

Axial Porosity in an 8-ton steel ingot

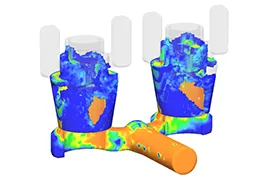

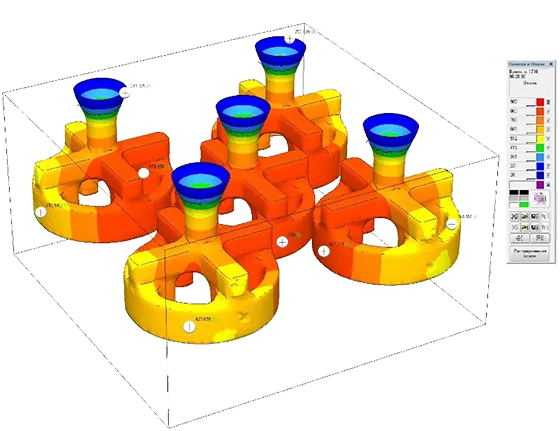

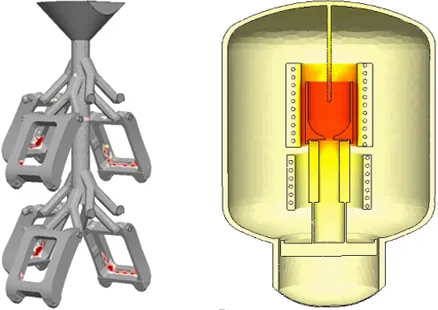

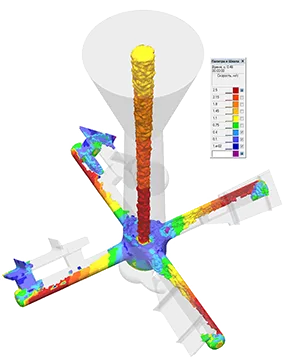

Heat Transfer by Radiation

PoligonSoft can solve complex radiation heat transfer tasks, taking into account re-radiation and shading.

This is important not only for vacuum casting but also for casting of foundry blocks on "trees" using the investment casting technology without the use of a supporting filler material.

The placement of castings on the tree, the location of the blocks relative to each other during casting and cooling, can significantly affect the porosity pattern.

Simulation of Internal Chillers

Internal chillers are made from the same alloy as the casting and are installed inside the mold cavity. During the mold filling with the alloy, the internal chillers partially or completely melt and weld with the base metal. The chillers can influence the thermal profile of the casting, its solidification, and prevent the occurrence of shrinkage porosity.

The ability to simulate this process is a feature that distinguishes PoligonSoft from many similar systems.

Explore Process Workspaces

EULER

Mold Filling Simulation.

The "Euler" module allows for the calculation of mold filling with molten mass at a constant or variable speed through one or several sprues.

It calculates the temperature drop of the molten metal when contacting the mold walls and the heat transfer to the surroundings, as well as solidification, which can lead to the flow stopping and filling defects.

A special algorithm enables investigating the operation of the sprue system, identifying its critical points, and finding optimal sizes, locations, and the number of risers.

- Temperature of the metal and the mold during filling

- Velocity fields of the molten metal

- Free surface of the molten metal

- Solidification dynamics

- Stopping criteria (filling defects)

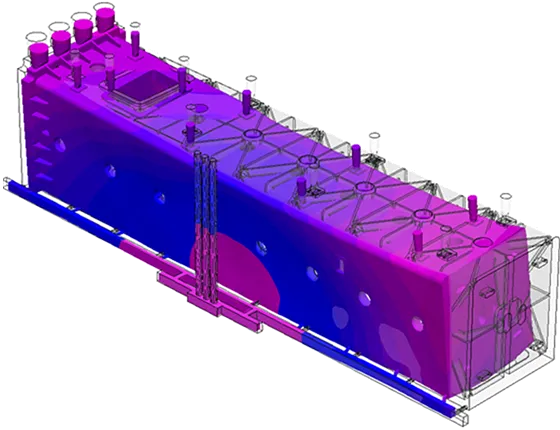

Large Castings

Thanks to the use of the finite element method, the "PoligonSoft" system is successfully used to model very large castings and, at the same time, comparatively thin-walled.

In combination with the ability to use symmetry and multithreading calculations, the modeling process takes a reasonably acceptable time. At the same time, the computational resources used (mainly the amount of RAM) do not exceed the limits of ordinary office PCs.

Dimensions: 8700х2000х2080 mm

Average wall thickness: 30 mm

The model contains: 677,700 nodes and 3,170,621 elements

HOOKE

Stress and Strain Solver.

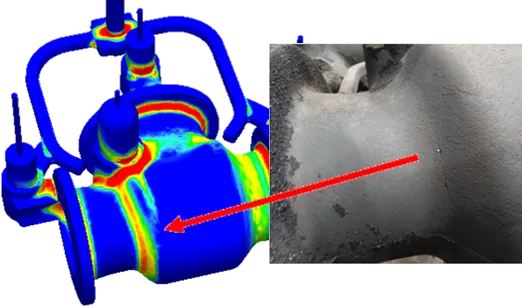

The "Hooke" solver is designed to calculate the residual stresses and strains that arise in the casting during cooling and interaction with the mold. An integrated algorithm predicts the formation of cracks and indicates areas of potential destruction.

The reliability and stability of the algorithms allow the solver to be used even for modeling thermal treatment processes (quenching in various media, annealing, tempering, etc.) to determine residual stresses, deformations, warping, and potential destruction both in the casting and the mold.

The calculation is based on the theory of small elastoplastic deformations created by A. Ilyushin and the Newton method. The module allows calculating:

- Magnitude and distribution of residual stresses

- Magnitude and distribution of strains

- The warping of the casting in general and according to the coordinate axes

- The locations of potential cold and hot crack formation

Hot Crack Indicator (BAZ JSC).

Prediction of Cold Cracks (UEC JSC)

Centrifugal Casting

PoligonSoft includes specific models for analyzing mold filling and shrinkage porosity in centrifugal casting.

The user specifies the axis, direction, and speed of the mold's rotation.

Combined with the ability to simulate investment casting, it is an indispensable tool for the production of titanium alloy castings.

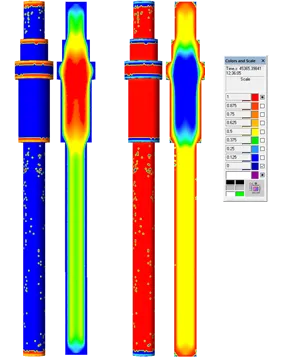

READ MOREContinuous Casting

PoligonSoft allows for the calculation of continuous casting.

It simulates the conditions of pre-start retention and traction with cooling of the metal in the crystallizer, in the cooling medium below the crystallizer, and then in the air.

The module enables the investigation of the influence of various technological parameters on the quality of the casting and the occurrence of defective parts.

READ MOREMacrostructure

The solver models the formation of the grain structure during the cooling of molten metal.

The solver takes into account the chemical composition, the degree of supercooling, and the number of nuclei on both the surfaces and within the volume of the molten metal.

The result shows the quantity, size, shape, and spatial orientation of the grains.

READ MOREHeat Treatment

Special module for the analysis of heat treatments in steels: quenching, normalizing, annealing, and tempering.

As a result of the analysis, the following is obtained:

- Structure (martensite, bainite, ferrite-pearlite mixture)

- Vickers Hardness

- Yield Strength

- Tensile Strength

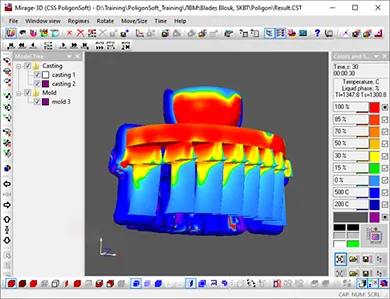

Mirage

The program is designed to visualize three-dimensional dynamic fields of scalar quantities (for example, time-varying temperature-phase fields), previously simulated in the processor modules of the PoligonSoft system.

Users can interact with the visualized data, adjusting parameters such as transparency, isosurface representation, and viewing features like shrinkage cavities and flow patterns.

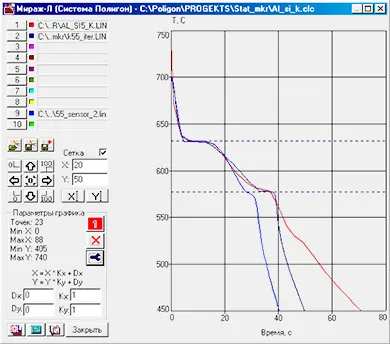

Mirage-L

A graphical visualization module that allows users to visualize curves or graphs that have been prepared in the "Mirage" module.

It allows loading up to ten graphs simultaneously, each with its own color indicator for easy identification in the coordinate field.

Additionally, it offers the option to construct new graphs from a formula provided by the user.

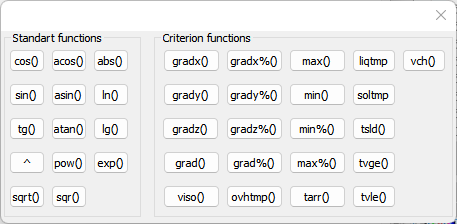

Criterion

A criteria analysis module for the obtained results

Properties and parameters such as structure, hardness, slag, mold wear, cooling rate, among others, can be calculated and analyzed.

The module includes a wide range of integrated functions that allow the user to create custom analysis criteria suited to the specific needs of their production, such as powers, logarithms, trigonometric functions, gradients, rates of change, searching for minimum and maximum values, and others